Features

Faster operation

■Simultaneous fiber preparation

Fiber preparation, stripping, cleaving, and setting in the splicer usually needs repeating separately for

both left and right-side fibers. The 45S process does away with that and enables simultaneous fiber

preparation thanks to the new SS05 fiber stripper, the new AD-16A fiber adapter for the CT50 cleaver

and the clever set plate mechanism of the 45S itself.

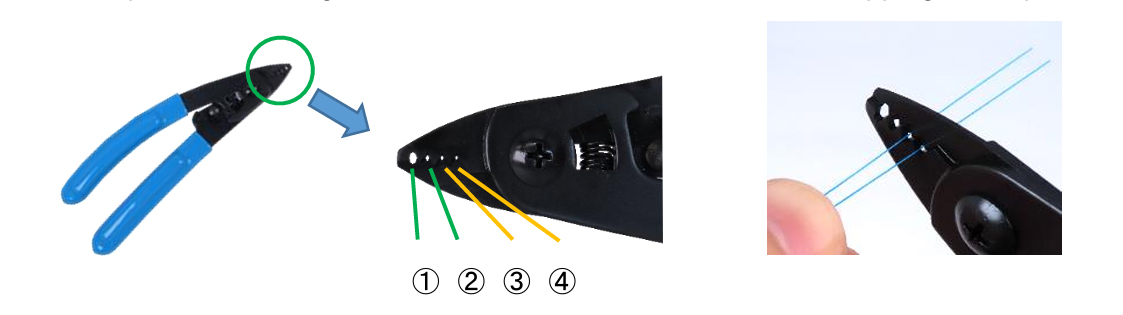

●Simultaneous fiber stripping

The SS05 fiber stripper is equipped with four blades: ① for 2mm/3mm, ② for 900µm,

③④ for 250µm fibers. Using blades ③ & ④ allows simultaneous stripping of 250µm fibers.

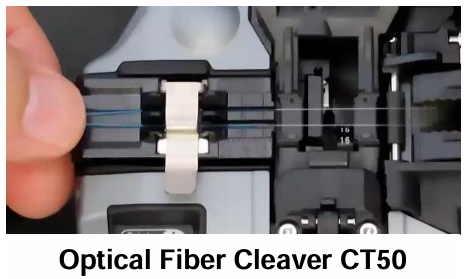

●Simultaneous fiber cleaving

The new AD-16A fiber adapter for the CT50 cleaver is

equipped with two grooves. Placing one fiber in each groove

provides simultaneous cleaving.

●Simultaneous fiber setting

Optical Fiber Cleaver CT50

Previous fusion splicers required two-handed operation to close fiber clamp and hold the fiber. Thanks to a

new clamp mechanism, the 45S close with fiber setting and provides one-handed fiber setting and

simultaneous fiber setting.

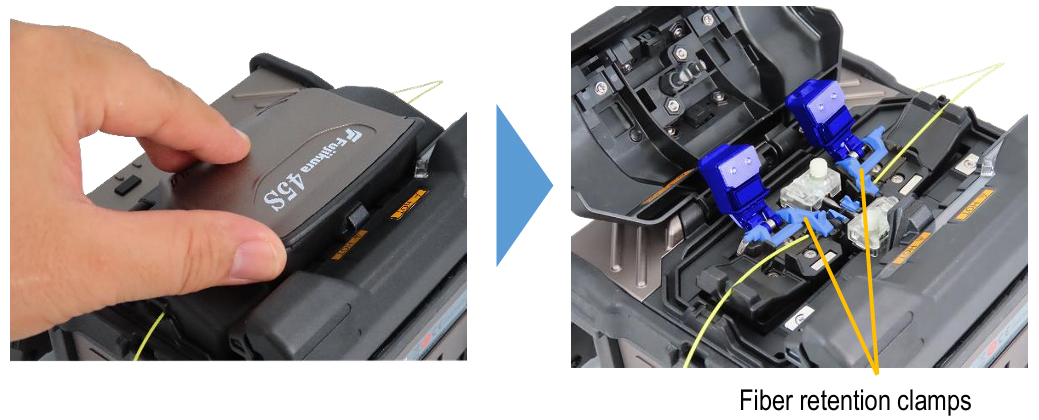

■Faster fiber transportation time

The 45S is equipped with a mechanism linking the wind protector and fiber clamp so when you open

wind protector, the fiber clamps open automatically.

The 45S is also equipped with retention clamps which are reputed by our conventional fusion splicer

models. The retention clamps prevent the fiber from jumping out after the fiber clamps are opened.

These mechanisms work in tandem to provide easy fiber handling and a reduction in the time it takes

to transfer the fiber to the heater.

■Faster heating time

The heater for shrinking the protection sleeve is designed to heat

the protection sleeve between two heaters in the front and rear.

It shortens 15% of the heating time in case of using FP-03 sleeve.

※Measured at room temperature with the AC adapter. The heat time is defined from the start beep sound to the finish beep sound. The

average heat time changes depending on the environmental conditions, sleeve type and battery pack condition. In addition, since the

heating operation is constantly optimized, the average heating time changes depending on the usage conditions of the fusion splicer.

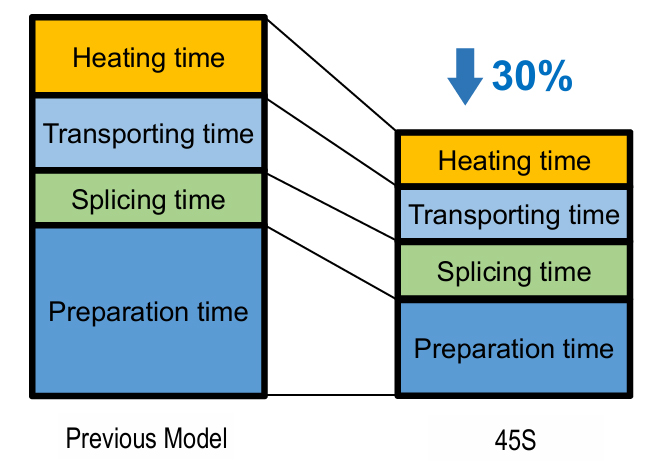

■30% faster than previous model

Thanks to the way the 45S streamlines the preparation process, reduces transport time and delivers

faster heating, it is 30% faster than the 41S+ it replaces.

User-friendly design

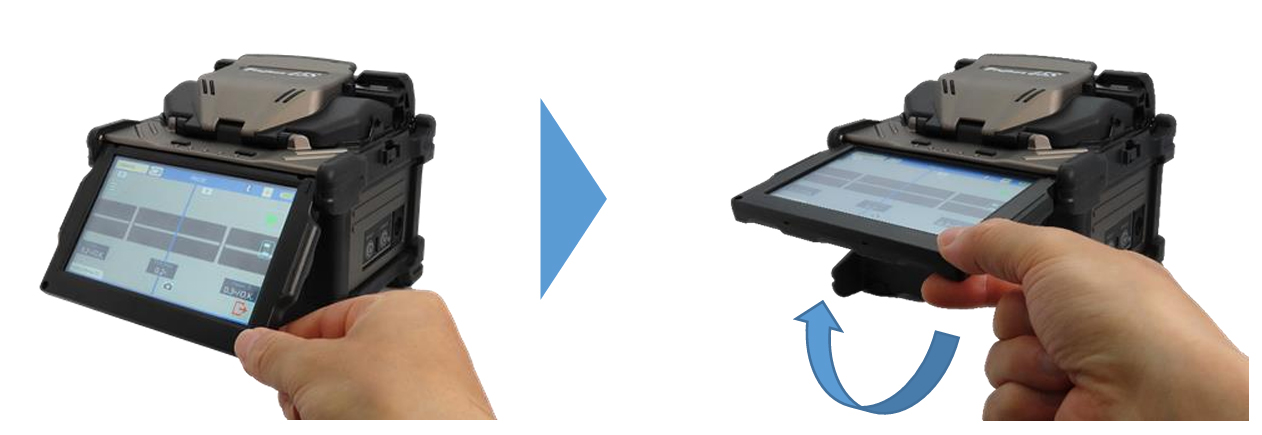

■Movable LCD monitor

The 45S is equipped with a movable 4.95-inch color LCD monitor to ensure optimum visibility in a

range of conditions, even when outside under direct sunlight.

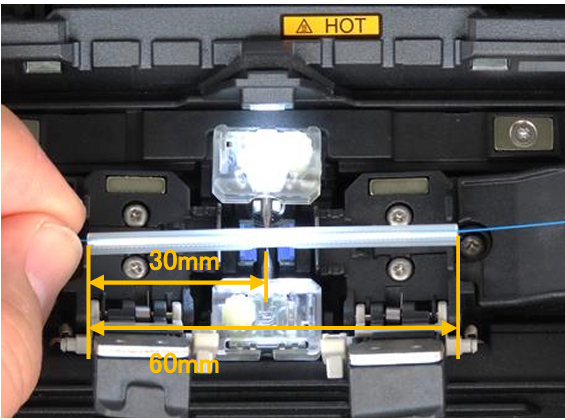

■Easy sleeve positioning

The space between the edges of the left and right fiber

clamp edges is 60mm, as per the image to the left.

This distance allows for easy sleeve positioning, with

the splice point positioned in the middle of the sleeve.

The scale on the heater shows the guide for other

sleeve lengths, for example 40mm.

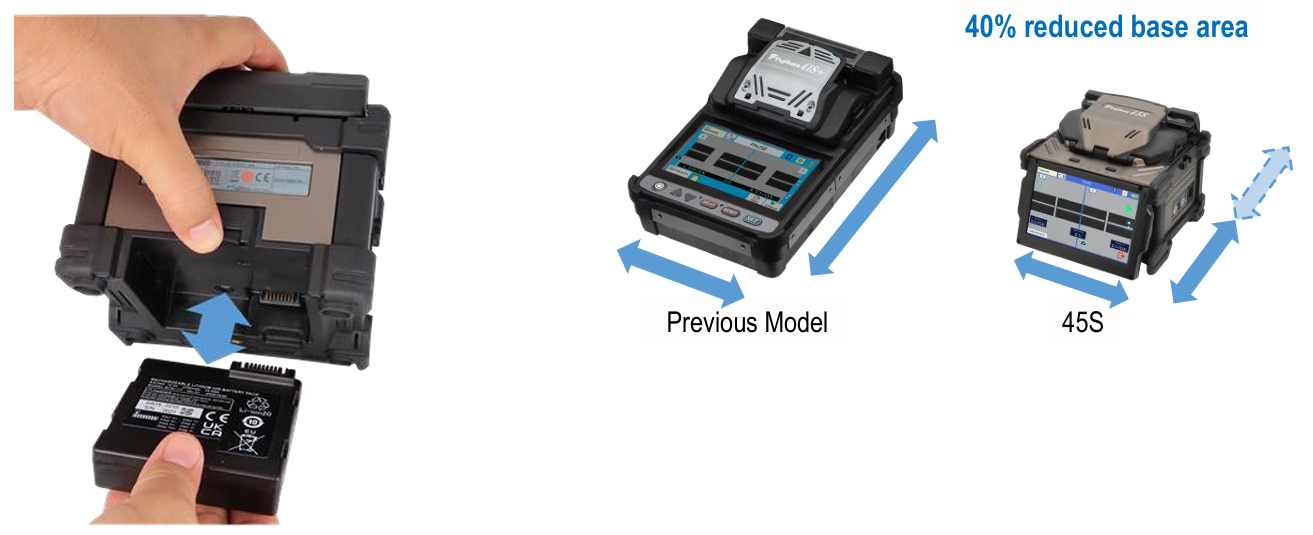

■Removable battery

The removable battery makes replacement easy

and convenient.

■Smaller footprint

The cube shape provides a reduced base area

while also giving the user a large operating space.