OPGW outdoor 24core 48core 96core 144core g652d stranded optic fiber cable ground wire fiber optic Cable Optical Power Ground wire 48core opgw cable opgw wire opgw 24 fiber fiber optic opgw wire single mode 48 cores opgw opgw 36 fibras g.652d opgw

Characteristic

Good mechanical and temperature performance

High strength loose tube that is hydrolysis resistant

Special tube filling compound ensure a critical protection of fiber

Specially designed compact structure is good at preventing loose tube from shrinking

Crush resistance and flexibility

Steel wire used as the central strength member

loose tube filling compound100% cable core filling

PSP enhancing moisture-proof

Application

Optical fiber composite ground wire [OPGW] is suitable for installation on new power lines with double function of ground wire and communication. Especially for installation on normal voitage and extra high voltage power lines. OPGW can replace conventional ground wire of old power line with increasing fiber communication function. They conduct short circuit current and provide lightning resistance.

Features

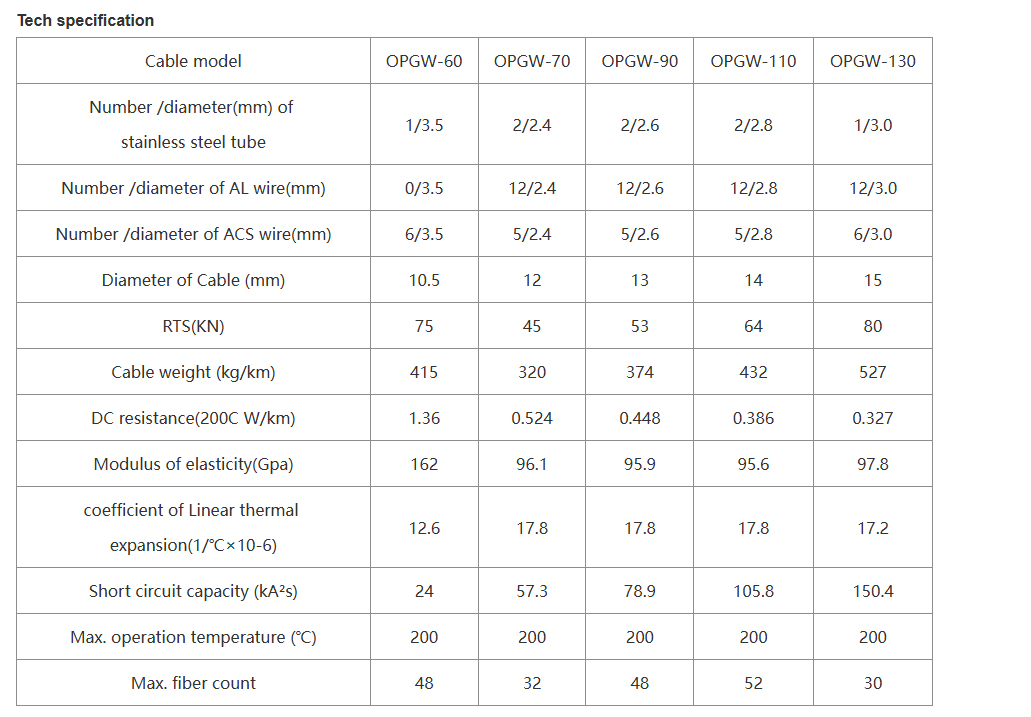

1. Up to 144 fibers

2. Cable diameter and weight approximate with another ground wire. Less additional load to tower, high tensile strength.

3. Excellent stainless steel tube stranding technology make the fibers have good secondary excess length and allow the fibers free movement in the tube. Which keeps the fiber stress-free while the cable is subjected to longitudinal stress.

4. Optical fibers are protected by stainless steel tubes.

5. Excellent security, good bullet resist performance.

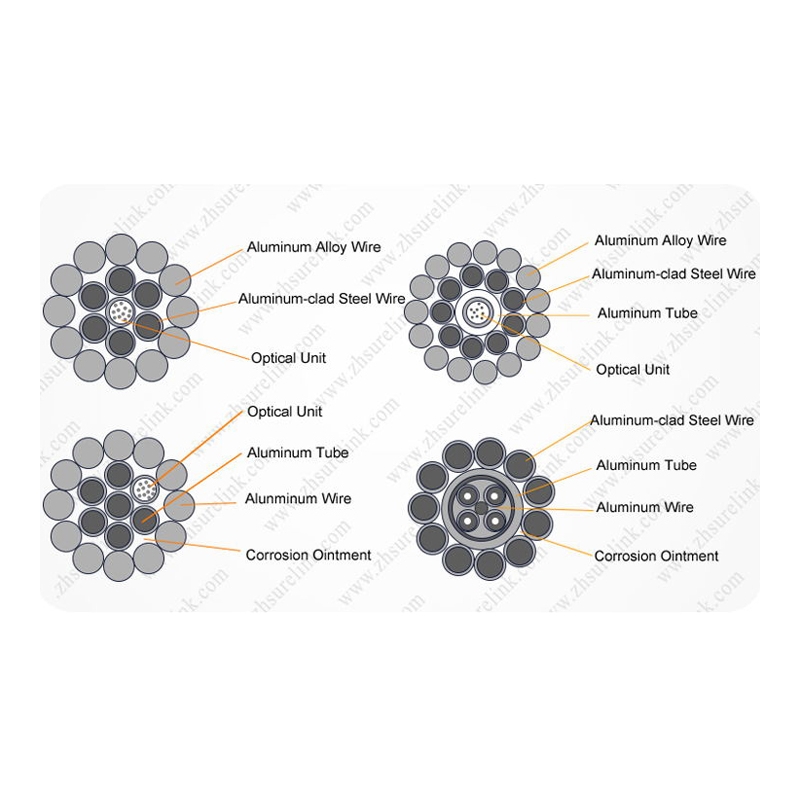

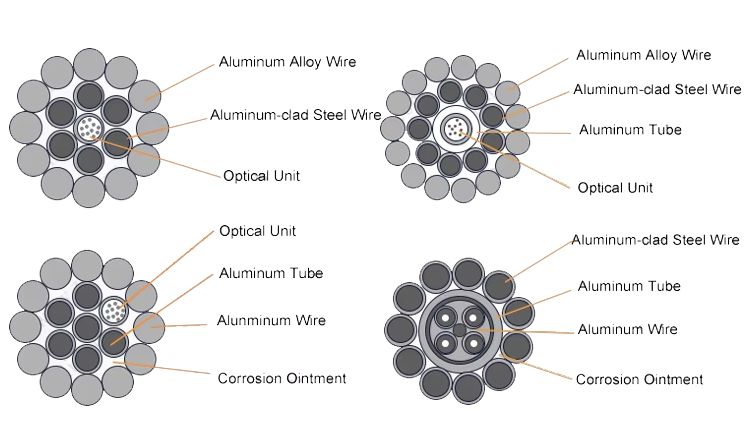

6. ACSW, AAW and SST stranded design provide wide range combination of electrical conductivity and mechanical tensile strength.

Superior Lightning Resistance

• Fewer Aluminium Alloy (AA) wires are needed to meet electrical specs

• More/Heavier duty ACS wires can be used

• AA wires can be completely replaced with ACS in some applications

Extruded Aluminium Core tube

• Good combination of crush and kink resistance

• Core tube can safely and easily be routed to closures without armour

• Easy access to optical core Superior

Electrical Performance

• Aluminium core tube substantially increases conductor cross-section

• Improved short-circuit capacity

High performance. Even in High fibre Counts

• All fibres are housed in the core tube

• Core tubes are available in a wide range of Inside Diameters

• Armour wires are not replaced with fibre tubes in high count designs